3.7 Given a scenario, install and replace printer consumables

- Laser

- Imaging drum, fuser assembly, transfer belt, transfer roller, pickup rollers, separation pads, duplexing assembly

- Imaging process: processing, charging, exposing, developing, transferring, fusing, and cleaning

- Maintenance: Replace toner, apply maintenance kit, calibrate, clean

- Inkjet

- Ink cartridge, print head, roller, feeder, duplexing assembly, carriage belt

- Calibration

- Maintenance: Clean heads, replace cartridges, calibrate, clear jams

- Thermal

- Feed assembly, heating element

- Special thermal paper

- Maintenance: Replace paper, clean heating element, remove debris

- Heat sensitivity of paper

- Impact

- Print head, ribbon, tractor feed

- Impact paper

- Maintenance: Replace ribbon, replace print head, replace paper

- 3D Printers

- Filament

- Resin

- Print Bed

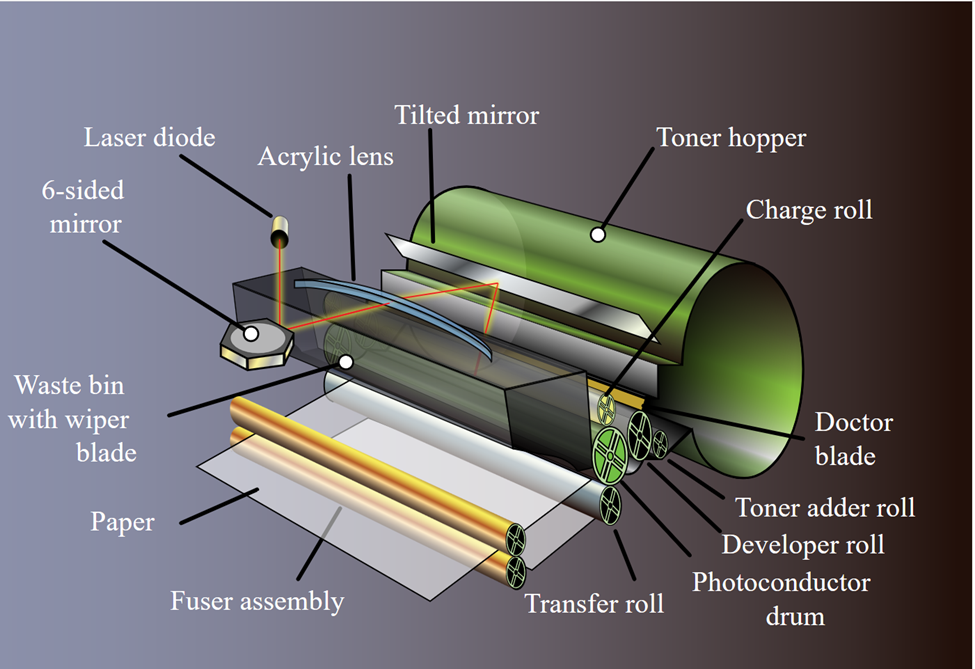

Laser Printer

A laser printer has many parts. Before we can replace anything, we should learn how it works.

A color laser printer has the same process a black and white laser printer. The difference is that there are four toner cartridges (black, yellow, cyan, and magenta). There is a separate system for each color. One color is applied to a sheet at a time. The laser print process is repeated four times in a color laser printer. Each of the four systems must align perfectly, or colors on the printed page won’t line up. Remember that when we combine yellow, cyan, and magenta, we can generate any other color.

The standard laser printer process

- Processing

- The printer receives the document from the computer and converts it into an image

- The image is a grid of dots across the page, each of which is a different color (for color printers), or black/white for black/white laser printers

- This is known as a raster image

- The laser printer processes one page at a time

- The printer receives the document from the computer and converts it into an image

- Charging

- The charge roller applies a negative electric charge to the imaging drum

- The charge roller applies a negative electric charge to the imaging drum

- Exposing

- The laser strikes the drum at locations where the toner should stick, converting the negative charge to a positive charge

- The laser strikes the drum at locations where the toner should stick, converting the negative charge to a positive charge

- Developing

- The toner has a negative charge. It is attracted to the portions of the drum which have a positive charge and sticks there

- Now we have our image in toner on the drum

- The toner has a negative charge. It is attracted to the portions of the drum which have a positive charge and sticks there

- Transferring

- The paper (which has a positive charge) is attached to the drum

- The paper picks up the negatively charged toner from the drum

- The paper (which has a positive charge) is attached to the drum

- Fusing

- The paper travels to the fuser

The fuser melts the toner to the paper through heat and pressure

- The paper is ejected from the printer

- The paper travels to the fuser

- Cleaning

- The printer cleans the drum

Laser Printer Maintenance Procedure

- Replace each toner cartridge when it is empty

- Empty or replace the waste toner bottle (if the printer is equipped with one)

- Use a dry cloth to clean the inside of the printer when dirty

- Print a configuration page. The page will list the most recent errors.

- Look up the errors in the maintenance manual to determine what other actions to take.

- Look up the errors in the maintenance manual to determine what other actions to take.

- Print a cleaning page. The cleaning page will clean the inside of the printer.

- Replace the

- Fuser

- Separation Pad

- Pick Up Roller

- Transfer Roller

- Imaging drum, if necessary

- Developer unit, if necessary

- Other components as determined by the manufacturer

- Typically, the fuser, separation pad, pick up rollers, and transfer roller are sold together as part of a maintenance kit. They all tend to wear out at the same time. The printer will keep track of the number of pages printed, and when it reaches a certain level, it will register a “maintenance” error. Maintenance is typically required after 200,000 pages, but this varies between printer makes and models.

- Check the maintenance manual for instructions on how to replace each component.

- It is difficult to change parts in older printers. Many steps are required, and many components must be removed.

- It is easy to replace parts in newer printers. Many parts are held in by plastic tabs; no tools are required.

- It is difficult to change parts in older printers. Many steps are required, and many components must be removed.

- If you have a maintenance contract with a printer manufacturer, then

- The printer will keep track of its supplies

- When supplies run low, it will send an alert to the manufacturer over the internet

- The manufacturer will ship replacement supplies to you

- The printer will keep track of its supplies

Inkjet Printer

A laser printer has many parts. Before we can replace anything, we should learn how it works.

| Ink Cartridge | The ink cartridge holds ink. A printer may have one or more ink cartridges |

| Print Head | The print head holds the print cartridges The print head transfers ink from the cartridge to the paper Print heads wear out or become clogged with ink They must be cleaned when plugged and replaced when worn out |

| Roller | The roller ejects paper from the printer |

| Feeder | The feeder feeds paper into the printer |

| Duplexing Assembly | The duplexer flips the paper over so that the printer can print on the other side It is rarely found on inkjet printers |

| Belt | The belt moves the print head from side to side so that it can cover the entire sheet |

Inkjet Maintenance Procedure

- It is necessary to calibrate an inkjet printer before use. Calibration forces the print head to line up with the edge of the paper correctly.

- We should also clean the print head regularly and replace it when it is worn.

- We should replace the ink cartridges when they run low

Thermal Printer

A thermal printer prints on special thermal paper or thermal labels. When heated, the paper generates an image or text. When you insert a roll of labels into a thermal printer, it can automatically detect the end of the label (where one label starts and another label ends). How?

- A laser in the printer shines through the roll

- A sensor tracks how much light passes through the roll

- When lots of light passes through, the printer knows that the roll is at the seam. When a small amount of light passes through, the printer knows that the laser is shining through the label.

This might require automatic or manual calibration.

A Thermal Printer has three main components

| Sensor | Detects the position of the paper/media |

| Feed Assembly | Feeds the paper into the heating element |

| Heating Element | The heating element heats the paper, creating images and text. |

Thermal Printer Maintenance

- We should clean the heating element regularly.

- We should also clean the internal sensors.

- We might need to manually recalibrate the printer

- The printer also has belts and rollers that need to be replaced regularly

Impact Printer

An Impact Printer uses a ribbon and hammers to print out a document. You can think of it like an automatic typewriter.

- The paper is pulled through the printer

- The printer pulls a ribbon between the paper and a bank of hammers

- The hammers strike the ribbon

- Each strike deposits a small amount of ink from the ribbon onto the paper

Impact Printer Maintenance

- We should replace the ribbon when it is used

- We should clean the print head (hammers). The hammers might need to be cleaned with silicone spray.

- The printer’s internal components need to be cleaned with a dry cloth

- We may also need to calibrate the printer

3D Printing

A 3D printer will build a 3D object one layer at a time. It will deposit a layer of plastic and continue to build on top of it until all the layers are complete. There are several methods of printing in 3D and a wide variety of raw materials available, each with its own properties. The two main types

- Filament. The filament printer’s “ink” is a plastic string known as a filament. The filament passes through a nozzle, where it is melted and is deposited onto the print bed. The filament quickly solidifies. This process is known as Fused Deposition Modeling or FDM.

- Resin. The resin printer’s “ink” is a resin, which is a liquid. The printer deposits a thin layer of resin. A UV light shines onto the layer and cures it. The printer continues to deposit additional layers of resin, which are cured. This process is known as Stereolithography.

A resin printer is more expensive but produces more detailed prints.

3D Printer Maintenance

- We must calibrate the printer

- We should clean the print bed

- We should clean the nozzle. Nozzles get plugged.